Some Known Details About Lean Manufacturing s

Wiki Article

The 15-Second Trick For Manufacturing Industries

Table of ContentsHow Additive Manufacturing can Save You Time, Stress, and Money.The 45-Second Trick For MfgSee This Report on Plastic ManufacturingThe Single Strategy To Use For OemThe Ultimate Guide To Lean ProductionNot known Details About Oem

The text on this web page is a sample from our full White Paper 'Shot Moulding for Purchasers' - * Example message * - for full overview click the download switch over! Intro This overview is intended for people who are looking to resource plastic mouldings. It gives a much required understanding right into all that is involved with creating plastic components, from the mould device called for to the moulding procedure itself.If you intend to discover further, the guide covers kinds of mould devices, along with special finishing processes such as colours & plating. Words that are underscored can be found in the glossary in the appendix ... Part I: Moulding: The Essentials The Advantages of Injection Moulding Plastic injection moulding is a very accurate procedure that supplies numerous advantages over other plastic handling approaches.

Precision is best for really elaborate components. Contrasted to various other techniques, moulding allows you to include more features at extremely little tolerances. Take a look at the image to the right. lean manufacturing. You can hold this moulding in the palm of your hand and also it has bosses, ribs, steel inserts, side cores as well as openings, made with a sliding shut off function in the mould device.

Additive Manufacturing - Questions

How Die Casting can Save You Time, Stress, and Money.

from material feed & melting; material injection; cooling time and ejection to the re-closing of the mould tool ready for prepared next cycleFollowing Draft angles - The walls of a moulded part must be slightly tapered in the direction in which the part is ejected from the mould device, to permit the component to be ejected easily.Ejector stroke - The pressing out of ejector pins to expel the moulded part from the mould device. Ejector stroke rate, length as well as timing needs to be carefully managed to stop damages to the ejectors as well as mould device, yet at the very same time make the moulding cycle as brief as possible.

The 45-Second Trick For Die Casting

Ribs - When a plastic part has slim wall surfaces, ribs are contributed to the design to make the thin wall surfaces more powerful Side cores - Side action which produces a function on a moulded part, at an opposing angle to the regular opening direction of the mould tool. additive manufacturing. The side core requires to be able to withdraw as the plastic part can not be expelled otherwise.

Wall surfaces - The sides of a moulded part The message on this page is a sample from our full White Paper 'Injection Moulding for Customers'.

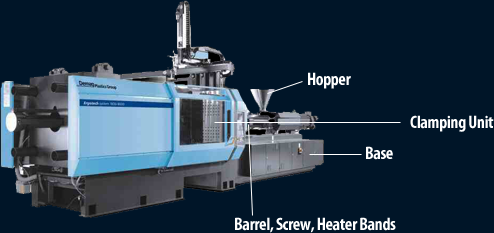

Injection moulding is commonly used for producing a selection of parts, from the smallest parts to whole body panels of cars and trucks. Injection moulding utilizes a special-purpose equipment that has three parts: the shot unit, the mould as well as the clamp.

The Best Guide To Plastic Manufacturing

, with the quantity utilized of the former being considerably higher.: 13 Thermoplastics are widespread due to qualities that make them highly ideal for shot moulding, such as convenience of recycling, adaptability for a large range of applications,: 89 as well as capacity to soften and move on heating.In multiple dental caries moulds, each tooth cavity can be similar as well as develop the exact same components or can be one-of-a-kind and also form several various geometries throughout a single cycle. Moulds are normally made from tool steels, but stainless steels and more information aluminium moulds are appropriate for sure applications. Aluminium moulds are typically improper for high volume production or get rid of narrow dimensional resistances, as they have inferior mechanical homes and also are a lot more prone to put on, damage, as well as contortion throughout the injection and also securing cycles; however, aluminium moulds are economical in low-volume applications, as mould fabrication prices and time are substantially decreased.

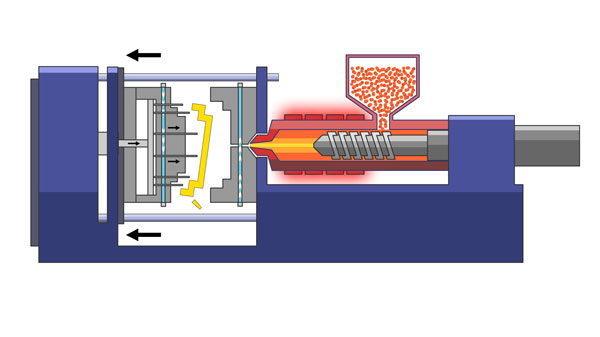

The screw supplies the raw material onward, blends and also homogenises the thermal as well as thick circulations of the polymer, and minimizes the needed heating time by mechanically shearing the product as well as adding a considerable quantity of frictional home heating to the polymer. The product feeds forward with a check shutoff and also gathers at the front of the screw right into a volume known as a shot. When enough product has gathered, the product is required at high stress as well as velocity right into the component creating dental caries. The exact quantity of contraction is a function of the resin being utilized, as well as can be relatively predictable. To protect against spikes in pressure, the procedure typically makes use of a transfer position representing a 9598% full dental caries where the screw changes from a consistent velocity to a consistent pressure control.

Additive Manufacturing for Beginners

As soon as the screw reaches the transfer position the packing stress is used, which finishes mould filling and also makes up for thermal contraction, which is quite high for thermoplastics about numerous various other products. The packaging pressure is applied till eviction (dental caries entryway) strengthens. As a result of its small dimension, eviction is generally the top place to solidify with its whole thickness.: 16 Once eviction strengthens, no even more material can enter the cavity; appropriately, the screw reciprocates and also obtains product for the following cycle while the product within the mould cools down so that it can be expelled and be stainless steel suppliers dimensionally stable.Report this wiki page